The Complete Guide to Label Substrates: From Paper to BOPP to Cryo

Introduction

When it comes to label substrates, the material beneath the ink matters just as much as the design on top. This foundation determines whether your label will survive a freezer, attract attention on a shelf, or peel away after a few hours. Because of this, choosing the right label substrate is one of the most important steps in packaging design. In this guide, we’ll explore the most common substrate types, explain when to use each, and show how industries such as biotech, food, and logistics rely on them.

What Are Label Substrates?

A label substrate is the base material a label is printed on, and it defines structure, appearance, and durability. In other words, it’s what gives the label its backbone.

Substrates work alongside adhesives and finishes, yet each plays a distinct role. Think of it this way: the substrate is the canvas, the adhesive the glue, and the finish the protective layer.

The right label substrate affects:

-

Print quality

-

Resistance to moisture, chemicals, and abrasion

-

Overall brand appearance

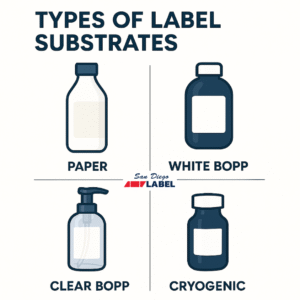

Common Types of Label Substrates

1. Paper Label Substrates

Paper label substrates are affordable, simple to print, and ideal for short-term or indoor applications. However, paper is not moisture-resistant, so it’s unsuitable for refrigeration or outdoor products.

Best for: dry food, retail packaging, and promotional stickers.

Tip: Add a matte laminate for extra protection and a natural finish.

2. Film-Based Label Substrates

Films provide higher durability, flexibility, and resistance to water and chemicals. For example, many consumer products use these materials for long shelf life. Common options include:

-

White BOPP: A versatile, moisture-resistant film that prints cleanly and resists tearing.

-

Clear BOPP: Offers a “no-label” look, ideal for cosmetics and transparent containers.

-

Metallic Films: Create a premium, reflective finish perfect for wine or luxury packaging.

-

PET, Vinyl, and Polyimide Films: Durable synthetics for industrial or outdoor use.

For current market trends in durable and sustainable film materials, visit Label & Narrow Web’s overview of film substrates.

3. Specialty Label Substrates

Some industries depend on materials built for extreme conditions. For instance, biotech labs and warehouses use specialized constructions such as:

-

Cryogenic Substrates: Designed for biotech and lab storage, these films endure ultra-low temperatures without losing adhesion.

-

Thermal Transfer & Direct Thermal: Perfect for barcoding and logistics because they resist smudging and remain scannable.

-

Durable Industrial Films: Provide UV and chemical resistance for outdoor or chemical environments.

Ultimately, each label substrate fulfills a specific function—from sample tracking to heavy-duty product labeling.

How to Choose the Right Label Substrate

Selecting the right substrate depends on your product, environment, and cost goals. To begin with, assess these key factors:

-

Environment: Will the label face moisture, sunlight, or chemical exposure?

-

Durability: Short-term campaigns can use paper, whereas long-term items require film or specialty materials.

-

Appearance: Clear BOPP suits modern minimalist designs, while metallic finishes add luxury appeal.

-

Print Method: Match substrates to your print process—digital, flexo, or thermal transfer.

-

Budget: Paper offers low cost; films and cryo options cost more but deliver higher ROI.

Therefore, the best material balances performance, visual impact, and cost efficiency.

Industry Use Cases for Label Substrates

Different industries rely on label substrates for specific needs.

-

Food & Beverage: BOPP substrates resist oils and condensation, ensuring labels stay intact.

-

Biotech & Pharma: Cryogenic materials maintain adhesion during deep-freeze storage.

-

Industrial & Logistics: Thermal transfer films remain scannable despite heavy handling.

-

Cosmetics & Personal Care: Clear BOPP produces a clean, “no-label” appearance.

As a result, every sector benefits when the substrate matches its environment.

The Future of Label Substrates

Sustainability continues to shape label substrates. Recyclable films, compostable paper, and thinner materials reduce waste and shipping weight. Meanwhile, smart labeling technologies like RFID and NFC are embedding directly into substrates — making packaging interactive and traceable.

Conclusion

Sustainability continues to reshape label substrates. Meanwhile, recyclable films, compostable papers, and thinner gauges reduce material waste and shipping weight. In addition, smart labeling technologies such as RFID and NFC are embedding directly into substrates—creating interactive packaging that connects products with digital data.

👉 At San Diego Label, we help brands in biotech, food and beverage, and industrial sectors select the right substrate for their needs. Contact us today to request samples or talk through your project with our team.