Introduction

An effective FDA label design must look good and meet the rules. One small mistake can cause reprints, recalls, or even fines. In addition, errors slow down production and damage trust with buyers.

At San Diego Label, we help brands spot problems early so their labels meet all requirements before printing.

1. Missing or Incorrect Warning Placement in FDA Label Design

If a warning is hidden under a fold or printed too small, it does not meet FDA and Prop 65 rules. As a result, your product can fail inspection.

Fix: Always place the warning on the main display panel. In addition, use the approved font size and strong color contrast so buyers can see it clearly.

2. Poor Color Contrast or Low Legibility

Problem: Warnings must be conspicuous under normal use. Faint text or low-contrast colors fail FDA labeling readability standards.

Fix: Use bold black text on a bright background and confirm readability under natural and fluorescent light.

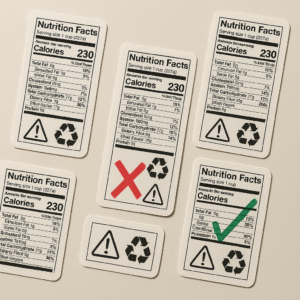

3. Inconsistent Typography or Symbol Formatting in FDA Label Design

Problem: Changing icons or typography in required warnings can make your FDA label design invalid.

Fix: Follow standard ⚠️ symbols, uppercase “WARNING,” and typefaces defined by Prop 65 or GHS guidelines.

4. Wrong Material for Product Environment

Problem: A compliant design printed on the wrong substrate can still fail. Peeling or smearing makes a label unreadable — violating FDA durability standards.

Fix: Match label materials and adhesives to the product’s environment: temperature, moisture, or chemical exposure.

5. Missing Supplier Verification

Problem: Compliance can break when suppliers skip material declarations.

Fix: Always request supplier verification forms confirming inks, coatings, and adhesives meet FDA and Prop 65 requirements as outlined by the U.S. Food and Drug Administration

6. No Version Control or Proofing System for FDA Label Design

Problem: Outdated artwork is one of the top FDA label design errors we see.

Fix: Implement strict version control and require proof approvals before every print run.

Conclusion

FDA label design compliance isn’t a one-time task — it’s an ongoing process. The right layout, materials, and proofing systems protect both your customers and your brand.

At San Diego Label, we build compliance into every phase — from file setup to final rewind — ensuring your labels print right the first time. Explore our Label Printing Services to see how we integrate FDA compliance into every step.