The Complete Guide to Label Substrates: From Paper to BOPP to Cryo

Introduction

When it comes to labels, the material beneath the ink matters just as much as the design on top. This foundation — known as the substrate — determines whether your label will hold up in a freezer, stand out on a crowded shelf, or peel away after a few hours. Choosing the right substrate is one of the most important steps in creating packaging that performs.

In this guide, we’ll break down the most common types of label substrates, explain when to use each one, and show you how industries like biotech, food and beverage, and logistics rely on different materials.

What Are Label Substrates?

A label substrate is simply the base material a label is printed on. It’s what gives the label its structure, appearance, and durability.

Substrates work hand-in-hand with adhesives and finishes, but they are not the same. Think of the substrate as the “canvas,” the adhesive as the “glue,” and the finish as the “protective layer.”

The choice of substrate affects:

-

Print quality

-

Resistance to moisture, chemicals, and abrasion

-

Overall brand presentation

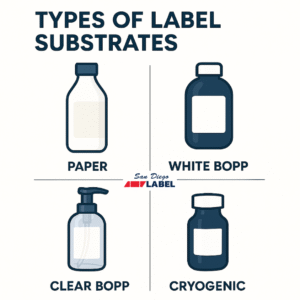

Common Types of Label Substrates

1. Paper

Paper substrates are the most affordable and widely used option. They are easy to print on and work well for short-term or indoor applications. However, paper is not moisture-resistant, making it less ideal for products exposed to water, oils, or refrigeration.

Best for: dry food products, retail items, promotional stickers

2. Film-Based Substrates

Films provide greater durability, flexibility, and resistance compared to paper. Within this category, there are several popular choices:

-

White BOPP – A versatile, moisture-resistant film with excellent printability. Ideal for food and beverage packaging.

-

Clear BOPP – Provides a “no-label” look, allowing packaging to show through. Popular in cosmetics and beverages.

-

Metallic Films – Adds a premium, eye-catching finish. Great for wine, spirits, and specialty products.

-

PET, Vinyl, and Polyimide Films – Durable synthetics used in harsh environments, often for industrial or electronics applications.

3. Specialty Substrates

Certain industries require materials engineered for extreme conditions:

-

Cryogenic Substrates – Designed for biotech and lab environments, these labels withstand ultra-low temperatures without losing adhesion. ([Internal link to Cryogenic Labels blog when live])

-

Thermal Transfer & Direct Thermal – Perfect for logistics, barcoding, and inventory management. They resist smudging and remain scannable under heavy use. ([Internal link to Thermal Transfer blog when live])

-

Durable/Industrial Substrates – Built for outdoor exposure, UV resistance, and contact with chemicals.

How to Choose the Right Substrate

The right material depends on your product, environment, and budget. Key factors include:

-

Environment – Will your label face freezing, refrigeration, or direct sunlight?

-

Durability – Short-term promotions can use paper, while long-term products need films or specialty substrates.

-

Appearance – Clear films for a sleek look, metallic for premium branding, matte paper for natural products.

-

Print Method Compatibility – Some substrates are better for digital runs, others for flexo or thermal transfer.

-

Cost – Paper is budget-friendly; films and specialty substrates require more investment but provide performance benefits.

Industry-Specific Use Cases

-

Food & Beverage – BOPP substrates resist condensation, oils, and moisture.

-

Biotech & Pharma – Cryogenic labels ensure compliance and durability in lab conditions.

-

Industrial & Logistics – Thermal transfer films provide clear, scannable barcodes and withstand heavy handling.

-

Cosmetics & Personal Care – Clear BOPP creates a high-end, “no-label” look on glass and plastic containers.

The Future of Label Substrates

Sustainability is driving innovation. Recyclable films, compostable paper stocks, and thinner materials designed to reduce shipping weight are becoming more common. At the same time, smart technologies like RFID and NFC are finding ways to integrate directly into substrates, making packaging both functional and interactive.

Conclusion

The substrate you choose is the foundation of your label — and the wrong choice can mean wasted money, compliance issues, or a poor customer experience. From affordable paper to high-performance cryogenic films, each material serves a purpose.

👉 At San Diego Label, we help brands in biotech, food and beverage, and industrial sectors select the right substrate for their needs. Contact us today to request samples or talk through your project with our team.